Tips to Avoid Wear on Machine Component

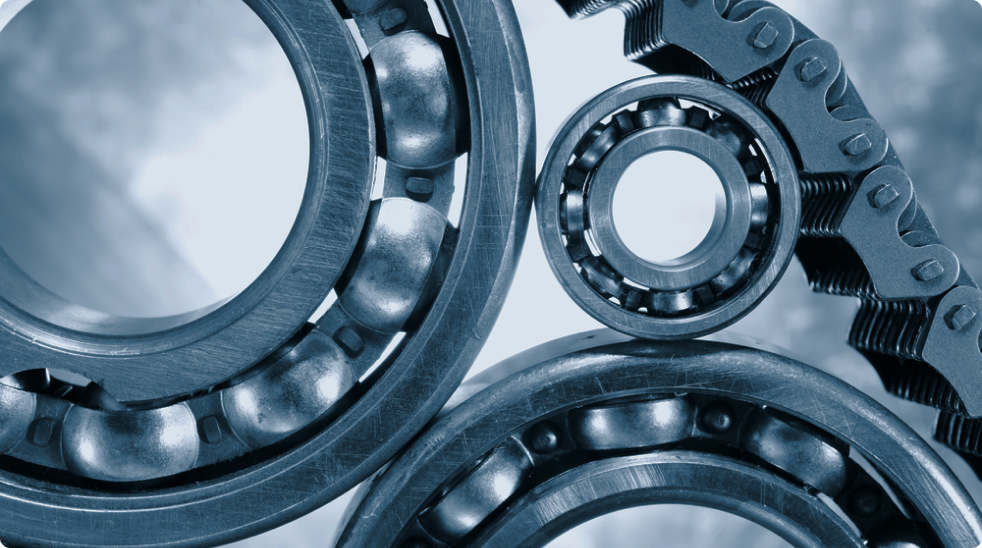

To avoid wear on machine components a good place to start is properly maintaining the bearings.

Bearings are an integral component in general machinery playing a vital role in transmitting loads, reducing friction, and supporting shafts. In many cases, bearings need little to no maintenance if selected and installed properly. However, as there are thousands of applications many solutions exist. Standard maintenance practices are fundamental in providing smooth operation and longer life. Smooth operating bearings result in reducing wear on mating machine components.

To help keep machines running smoothly we recommend the falling handling and maintenance steps for bearings:

- Store bearings in a cool clean low unity environment free of dust and avoid handling where shock and or vibration can come into play.

- Store bearings in their original undisturbed packaging laying flat on their face sides.

- Observe the manufacturer’s suggested storage time limits for lubrication. Lubrication can deteriorate or congeal and will need to be broken in or replaced if past the expiration date.

- Cleanliness is critical. All bearings should be kept clean as corrosion can shorten the life of the bearing considerably.

Mounting bearings. Several tips to do it right

Make sure the shaft and the housing are clean of any debris, are dimensionally accurate, and have no apparent damage. If dented or damaged take necessary steps to repair prior to installation.

When mounting the bearing components should never receive a direct impact from the installing tool. The rings, retainer, and rolling elements cannot directly absorb any shock due to mounting force. Use a fitting tool to properly mount the bearing such as the SKF TMFT36.

Mounting methods

There are two mounting methods often referred to as “HOT” or “COLD”.

Large bearings, usually those over 100mm in size, require using the Heat method. Using an induction heater to preheat the bearing races allowing for thermal expansion makes installation possible.

The “COLD” method is a mechanical mounting fit for small bearings including a press fit.

Lubrication is very important and the proper selection will result in higher longer lasting performance for reducing wear on machine components. For larger bearings and depending upon the application grease is normally specified. Oil is commonly used in small bearings.

Many bearings are lubed for life and are sealed in such a manner that grease is retained inside the bearing and cannot escape. In other cases, the grease must be delivered regularly to keep the machinery and its components operating smoothly while reducing wear.

The machine operator or maintenance person must keep a vigilant eye on how the lubricant is performing. In dirty or abrasive environments the grease can lose its lubricating properties and must be replaced. In some machines, it is advisable to install automatic lubricators. Automatic lubricators are a good solution over manual applications.

In avoiding additional wear in the machine it is imperative to take great care in dismounting bearings when replacing an older worn bearing.

- Use proper tools and methods and select bearings that meet all the same specifications as those that which is being removed. A bearing specification is more than just the part number stamped on its race. You must know the lubrication type, the fill percentage, the internal clearance and the type of cage, ball size, and number. Any deviation in specification can result in problems.

- Handling of the bearing and the components must be done with the utmost care. Damage to the shaft upon removal is a prescription for future failure of the bearing and operation of the machinery.